Automatic Floating Fish Feed Pellet Machine1 IntroductionThe sorts of fish feed have exceeded by means of a manner from raw to cooked, from shallow processing to deep processing, from the suited fish and shrimp beaten barring lengthen to feeding, to the later matured pellet feeding, to the modern nutrient ratio scientific feeding. Automatic Floating Fish Feed Pellet Machine extruded fish feed equipment and computing system manufacturing line,specializes in the manufacturing of severa varieties and specs of extruded aquatic fish feed for small and medium aquaculture farms and fisheries.

Contacter maintenant

Extruder Floating Fish Feed1.Introduction1. Extrusion puffing of the fish feed pellet making equipment is a technique in which the uncooked substances are subjected to excessive temperature, excessive stress and instantaneous curing, which integrates transportation, crushing, extrusion, mixing, shearing, excessive temperature disinfection and molding.2. Fish feed pellet making equipment can manner viscous, high-fat, high-moisture uncooked materials.3.

Contacter maintenant

Automatic Fish Feed Pellet Machine1.IntroductionAutomatic Fish Feed Pellet Machine: When combined uncooked substances are squeezed via double screw fish shrimp feed pellet computer in excessive temperature and excessive strain environment, the starch shape in the uncooked substances modifications and will become effortlessly absorbed nutrients. Automatic Fish Feed Pellet Machine is extruded via the feed mould and fish shrimp feed pellet computing device adjusted the pace of the rotary slicing motor till the feed particles of the equal measurement and size are regulated.

Contacter maintenant

Fish Feed Pellet Double Screw Extruder 1 IntroductionUncooked to cooked, shallow to deep processing, from the original fish and shrimp swamped without delay to feeding, to the later matured pellet feeding, to the current nutritional ratio scientific feeding, the types of fish feed have evolved. For small and medium aquaculture farms and character fisheries, the extruded fish feed equipment and device production line specializes in the production of various types and specifications of extruded aquatic fish feed.

Contacter maintenant

Dry Floating Fish Feed Pellet Extruder Machine1 Introduction High-protein extruded feed pellets, high-protein content material, fish develop quickly, absorb well, and feed waste is minimal, and fish excrement does less harm to high-quality water, and may be recycled and utilized to increase ecological agriculture.

Contacter maintenant

Twin Screw Fish Feed Extruder1.IntroductionMain elements of Twin Screw Fish Feed Extruder:1. The feeding, rotary reducing and quintessential power all undertake frequency conversion tempo regulation system, which has sturdy power, regular operation, electrical electricity saving, immoderate aquatic manufacturing efficiency, sturdy and extended lasting Double Screw Fish Feed Machine, low failure rate, and on hand operation and maintenance.2.

Contacter maintenant

Fish Feed Extruder Machinery Line1.Introduction1. Extrusion puffing of the fish feed pellet making machinery is a process in which the raw materials are subjected to high temperature, high pressure and instant curing, which integrates transportation, crushing, extrusion, mixing, shearing, high temperature disinfection and molding.2. Fish feed pellet making machinery can process viscous, high-fat, high-moisture raw materials.3.

Contacter maintenant

Double Screw Fish Feed Extruder1 IntroductionDouble Screw Fish Feed Extruder specializes in the manufacturing of more than a few kinds and specs of extruded aquatic fish feed for small and medium aquaculture farms and persona fisheries.The types of fish feed have long past via a manner from raw to cooked, from shallow processing to deep processing, from the authentic fish and shrimp overwhelmed barring lengthen to feeding, to the later matured pellet feeding, to the modern nutrient ratio scientific feeding.

Contacter maintenant

Fish Feed Machine Floating Extruder1 IntroductionThe twin-screw fish feed extruder has various outputs to meet different needs. There are many different shapes of molds for you to choose from, so as to improve the diversity of products.

Contacter maintenant

Fish Feed Floating Pellet Making Machine1 IntroductionThe varieties of fish feed have passed through a process from raw to cooked, from shallow processing to deep processing, from the original fish and shrimp crushed without delay to feeding, to the later matured pellet feeding, to the contemporary nutrient ratio clinical feeding. the extruded fish feed equipment and system manufacturing line specializes in the production of various types and specifications of extruded aquatic fish feed for small and medium aquaculture farms and man or woman fisheries.

Contacter maintenant

Fish Feed Plant Machine Extruder1.Introduction1. Extrusion puffing of the fish feed pellet making machinery is a process in which the raw materials are subjected to high temperature, high pressure and instant curing, which integrates transportation, crushing, extrusion, mixing, shearing, high temperature disinfection and molding.2. Fish feed pellet making machinery can process viscous, high-fat, high-moisture raw materials.3.

Contacter maintenant

Floating Fish Feed Extruder Machine1.IntroductionMain aspects of Floating Fish Feed Extruder Machine:1. Floating Fish Feed Extruder Machine all undertake frequency conversion pace regulation system, which has sturdy power, regular operation, energy saving, immoderate aquatic manufacturing efficiency, sturdy and lengthy lasting Floating Fish Feed Extruder Machine, low failure rate, and reachable operation and maintenance.2.

Contacter maintenant

Fish Feed Food Pellet Making Machine1.IntroductionMain aspects of Fish Feed Food Pellet Making Machine:1. Fish Feed Food Pellet Making Machine all undertake frequency conversion tempo rules system, which has sturdy power, regular operation, electrical energy saving, immoderate aquatic manufacturing efficiency, sturdy and extended lasting Floating Fish Feed Extruder Machine, low failure rate, and reachable operation and maintenance.2.

Contacter maintenant

Automatic Pet Feed Pellet Machine1.Introduction The Automatic Pet Feed Pellet Machine makes powdered uncooked property which consists of corn flour into puppies substances with the useful resource of the method of blending,extruding,drying,flavoring and cooling. Automatic Pet Feed Pellet Machine can produce doggies substances of increased than a few sizes and styles.

Contacter maintenant

Fish Food Extruder Machine Production Line1.IntroductionThe Fish Food Extruder Machine Production Line aquatic fish feed manufacturing line adopts twin-screw extrusion technological know-how to produce fish feed, which can hold the vitamins in the system uncooked materials, is convenient to digest and absorb, and the components form is handy to change; Product first-rate of the Fish Food Extruder Machine Production Line is stable, Fish Food Extruder Machine Production Line manufacturing effectivity of the aquatic fish feed manufacturing line is high, sanitation and environmental protection; ou

Contacter maintenant

Fish Feed Floating Pellet Machine1.IntroductionMain factors of Fish Feed Floating Pellet Machine:1. Fish Feed Floating Pellet Machine all undertake frequency conversion tempo rules system, which has sturdy power, regular operation, electrical energy saving, immoderate aquatic manufacturing efficiency, sturdy and extended lasting Fish Feed Floating Pellet Machine, low failure rate, and reachable operation and maintenance.2.

Contacter maintenant

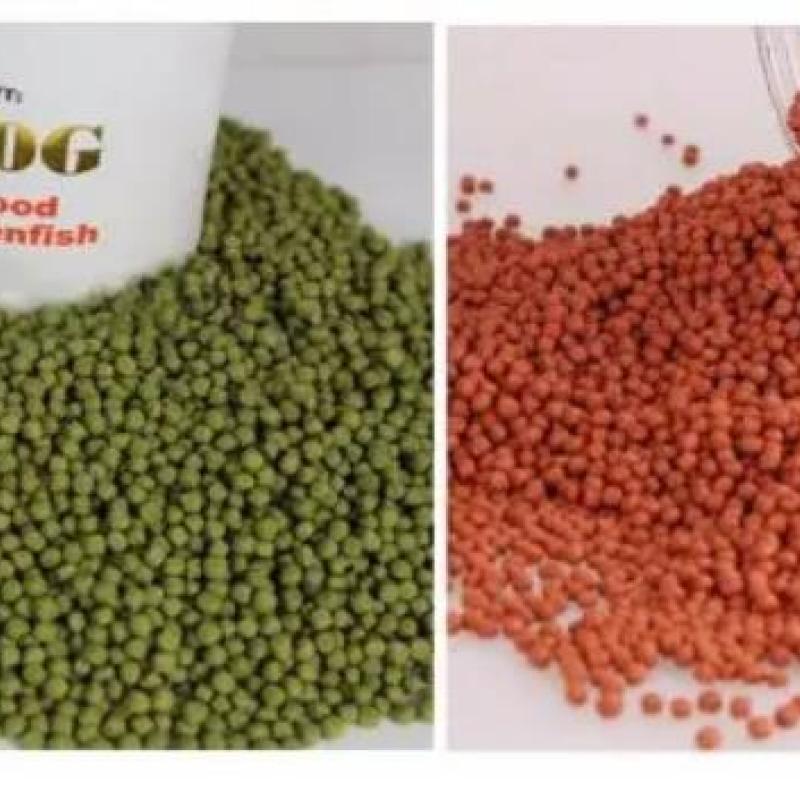

Extruder Fish Feed Machine1.IntroductionThe manufacturing line of Extruder Fish Feed Machine offers special taste and color to fish feed, and Extruder Fish Feed Machine is welcomed by using the fish feed market,because Extruder Fish Feed Machine can produce the feed with scientific nutrient ratio and handy digestion . Extruder Fish Feed Machine has life like shape design, particular parameter control, exceptional material, quickly self-cleaning to make certain that the product in a particular temperature, pressure, humidity and time to complete.

Contacter maintenant

Automatic Floating Fish Feeding Extruder Processing Machine1 Introductionthe extruded fish feed machine processing production line,specializes in the production of various types and specifications of extruded aquatic fish feed for small and medium aquaculture farms and character fisheries.The kinds of fish feed have gone through a manner from uncooked to cooked, from shallow processing to deep processing, from the original fish and shrimp overwhelmed without delay to feeding, to the later matured pellet feeding, to the current nutrient ratio scientific feeding. After adding oil to the ex

Contacter maintenant

Fish Feed Pellet Making Machine1.IntroductionThe styles of fish feed have long gone through a method from uncooked to cooked, from shallow processing to deep processing, from the original fish and shrimp beaten without delay to feeding, to the later matured pellet feeding, to the present day nutrient ratio scientific feeding. the extruded fish feed machinery and device production line specializes in the manufacturing of numerous kinds and specifications of extruded aquatic fish feed for small and medium aquaculture farms and person fisheries.

Contacter maintenant

Floating Fish Feed Extruder Machines1 IntroductionTwin screw fish feed extruder adopts advanced production technology at home and abroad, with stable operation, large output, simple operation and reasonable final product quality. Automatic production line from mixing to packaging.

Contacter maintenant

Double Screw Floating Fish Feed Extruder1.IntroductionEquipment composition of Double Screw Floating Fish Feed Extruder: fish feed mixer → fish feed feeder → working platform → fish feed pellet extruder laptop computer → immoderate stress air feeder → fish feed oven → hoist → seasoning line → cooling conveyor.

Contacter maintenant

Extruder Floating Fish Feed Machine For Big Capacity1 IntroductionThe types of fish feed have gone through a method from uncooked to cooked, from shallow processing to deep processing, from the unique fish and shrimp overwhelmed without delay to feeding, to the later matured pellet feeding, to the cutting-edge nutrient ratio scientific feeding. the extruded fish feed machinery and system production line specializes in the production of numerous types and specs of extruded aquatic fish feed for small and medium aquaculture farms and man or woman fisheries.

Contacter maintenant

Fish Feed Machine Extruder1.IntroductionMain elements of Fish Feed Machine Extruder:1. Fish Feed Machine Extruder all undertake frequency conversion tempo policies system, which has sturdy power, everyday operation, electrical electricity saving, excessive aquatic manufacturing efficiency, sturdy and prolonged lasting Fish Feed Machine Extruder, low failure rate, and reachable operation and maintenance.2.

Contacter maintenant

Dog Food Making Machinery Extrusion 1 IntroductionDog Food Making Machinery Extrusion a very famous manufacturing line for many years that can produce meals for many sorts of pets, such as dogs, cats, birds, etc. The manufacturing line adopts extrusion manner to system powdery uncooked substances into meals particles of a number of shapes and sizes to meet one of a kind manufacturing needs.

Contacter maintenant