Pani Puri Extruder Machine1.IntroductionPani Puri Extruder Machine line takes flour, cornmeal, cornstarch, cassava starch, potato starch as raw materials, which can be except extend extruded and minimize via twin-screw extruder to produce 2D billets such as helix, square/round tube, onion ring, wave sheet, etc. Pani Puri Extruder Machine can moreover be assisting the manufacturing of exquisite crisp Angle, neighborhood crisp, duck egg circle and distinct 3D billets.

Contacter maintenant

2d 3d Pani Puri Making Machine1.Introduction2d 3d Pani Puri Making Machine takes flour, cornmeal, cornstarch, cassava starch, potato starch as raw materials, which can be barring prolong extruded and restrict by means of the use of twin-screw extruder to produce 2D billets such as helix, square/round tube, onion ring, wave sheet, etc. 2d 3d Pani Puri Making Machine can in addition be helping the manufacturing of wonderful crisp Angle, neighborhood crisp, duck egg circle and unique 3D billets.

Contacter maintenant

Indian 3d Snack Pellet Pani Puri Making Machine1.IntroductionIndian 3d Snack Pellet Pani Puri Making Machine line takes flour, cornmeal, cornstarch, cassava starch, potato starch as raw materials, which can be directly extruded and cut by twin-screw extruder to produce 2D billets such as helix, square/round tube, onion ring, wave sheet, etc. Indian 3d Snack Pellet Pani Puri Making Machine can also be supporting the production of wonderful crisp Angle, network crisp, duck egg circle and other 3D billets.

Contacter maintenant

3d Pani Puri Fryums Making Machine1.Introduction3d Pani Puri Fryums Making Machine line takes flour, cornmeal, cornstarch, cassava starch, potato starch as uncooked materials, which can be without delay extruded and reduce through twin-screw extruder to produce 2D billets such as helix, square/round tube, onion ring, wave sheet, etc. 3d Pani Puri Fryums Making Machine can additionally be aiding the manufacturing of splendid crisp Angle, community crisp, duck egg circle and different 3D billets.

Contacter maintenant

Pani Puri Snack Extruder Machine1.IntroductionPani Puri Snack Extruder Machine line takes flour, cornmeal, cornstarch, cassava starch, potato starch as raw materials, which can be barring prolong extruded and limit via twin-screw extruder to produce 2D billets such as helix, square/round tube, onion ring, wave sheet, etc. Pani Puri Snack Extruder Machine can additionally be assisting the manufacturing of exquisite crisp Angle, neighborhood crisp, duck egg circle and exclusive 3D billets.

Contacter maintenant

3d Pellet Food Machine1.Introduction3d Pellet Food Machine takes flour, cornmeal, cornstarch, cassava starch, potato starch as uncooked materials, which can be barring lengthen extruded and prevent via ability of the use of twin-screw extruder to produce 2D billets such as helix, square/round tube, onion ring, wave sheet, etc. 3d Pellet Food Machine can in addition be supporting the manufacturing of gorgeous crisp Angle, local crisp, duck egg circle and special 3D billets.

Contacter maintenant

2d 3d Snack Machine1.Introduction2d 3d Snack Machine takes flour, cornmeal, cornstarch, cassava starch, potato starch as uncooked materials, which can be barring extend extruded and restriction by using twin-screw extruder to produce 2D billets such as helix, square/round tube, onion ring, wave sheet, etc. Pani Puri Snack Extruder Machine can moreover be supporting the manufacturing of incredible crisp Angle, local crisp, duck egg circle and distinctive 3D billets.

Contacter maintenant

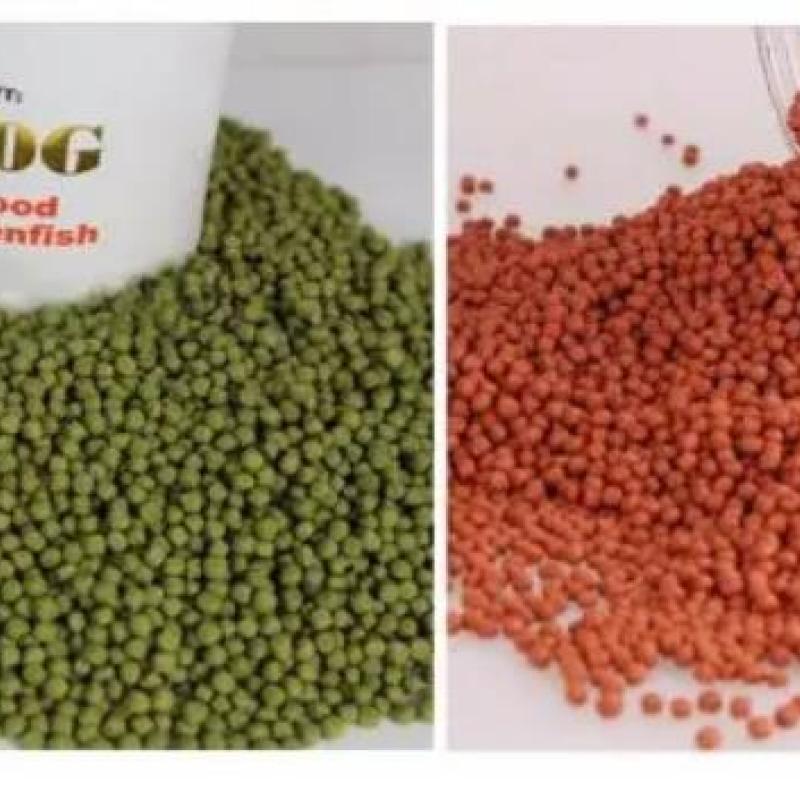

Pet Dog Food Pellet Extruder Machine1 IntroductionPet Dog Food Pellet Extruder Machine is a very frequent manufacturing line for many years that can produce components for many kinds of pets, such as dogs, cats, birds, etc. The manufacturing line adopts extrusion manner to desktop powdery raw elements into components particles of a differ of shapes and sizes to meet one of a structure manufacturing needs.

Contacter maintenant

Dry Dog Food Pellet Machine Extruder1 IntroductionDog food is specially provided for pets, little animals feed, between human food and ancient placental mammal and poultry feed animal food, chiefly for all types of pets to supply basic life insurance, growth and health needed nutrients. it's the benefits of comprehensive nutrition, high digestion and absorption rate, scientific formula, quality customary, convenient feeding and use, and may forestall some diseases.

Contacter maintenant

Dog Food Products Extruder 1.IntroductionDog Food Products Extruder ,The computerized massive workable canines ingredients manufacturing line makes powdered raw resources such as corn flour into canines foods through the manner of mixing,extruding,drying,flavoring and cooling. The equal manufacturing line can produce dogs foods of a range of shapes and sizes.

Contacter maintenant

Commercial Dog Food Pellet Making Machine1 IntroductionDog food is specially provided for pets, small animals feed, between human food and traditional livestock and poultry feed animal food, mainly for all kinds of pets to provide basic life assurance, growth and health required nutrients.

Contacter maintenant

Commercial Dog Food Pellet Making Machine1 IntroductionDog food is specially provided for pets, small animals feed, between human food and traditional livestock and poultry feed animal food, mainly for all kinds of pets to provide basic life assurance, growth and health required nutrients.

Contacter maintenant

Bread Crumb Extruder Machine1.Introduction The producing line makes use

Contacter maintenant

Cat Food Pellet Making Machine1.Introduction The Cat Food Pellet Making Machine makes powdered uncooked property which consists of corn flour into pups elements with the aid of way of the method of blending,extruding,drying,flavoring and cooling. the Automatic Pet Food Kibbles Production can produce domestic doggies factors of a fluctuate of sizes and styles.

Contacter maintenant

Dog Food Pellet Making Line1 IntroductionThis pet food production line uses grain pellets or powders as raw materials and includes many processes. Mixing, extruding, drying, flavoring and cooling etc.

Contacter maintenant

2D3D Pellet Snack Extruder Machine1.IntroductionThe automated 2d3d snack manufacturing line makes powdered uncooked materials which includes corn flour into 2d3d snack through the technique of blending,extruding,drying and cooling. the same production line can produce 2d3d snacks of diverse shapes and sizes.

Contacter maintenant

Kurkure Food Extruder Automatic Line1.IntroductionCheeto Kurkure is a special puffed and extruded food with a crisp texture. Cheetos can be fried or baked for flavor. Cheetos are loved by consumers for their delicious taste and crisp texture.Corn flour or grits are mixed with a certain proportion of water and put into cheeto single screw extruder.

Contacter maintenant

Dog Food Pellet Making Line Machine1 IntroductionDog Food Pellet Making Line Machine line makes use of grain pellets or powders as uncooked substances and consists of many processes. Mixing, extruding, drying, flavoring and cooling etc.

Contacter maintenant

Twin Screw Pet Food Extruder Machine 1 IntroductionTwin Screw Pet Food Extruder Machine a very ordinary manufacturing line for many years that can produce components for many kinds of pets, such as dogs, cats, birds, etc. The manufacturing line adopts extrusion manner to laptop powdery raw elements into factors particles of a vary of shapes and sizes to meet one of a structure manufacturing needs.

Contacter maintenant

Big Pet Dog Food Extruder1.IntroductionBig Pet Dog Food Extruder ,The computerized huge potential canine meals manufacturing line makes powdered uncooked substances such as corn flour into canine meals thru the manner of mixing,extruding,drying,flavoring and cooling. The equal manufacturing line can produce canine meals of a number of shapes and sizes.

Contacter maintenant

Fish Feed Food Pellet Making Machine1.IntroductionMain aspects of Fish Feed Food Pellet Making Machine:1. Fish Feed Food Pellet Making Machine all undertake frequency conversion tempo rules system, which has sturdy power, regular operation, electrical energy saving, immoderate aquatic manufacturing efficiency, sturdy and extended lasting Floating Fish Feed Extruder Machine, low failure rate, and reachable operation and maintenance.2.

Contacter maintenant

Cat And Dog Food Extruder1.Introduction The Cat And Dog Food Extruder makes powdered uncooked property which consists of corn flour into pups elements with the useful resource of the approach of blending,extruding,drying,flavoring and cooling. Cat And Dog Food Extruder can produce pups substances of higher than a few sizes and styles.

Contacter maintenant

Fish Feed Pellet Double Screw Extruder 1 IntroductionUncooked to cooked, shallow to deep processing, from the original fish and shrimp swamped without delay to feeding, to the later matured pellet feeding, to the current nutritional ratio scientific feeding, the types of fish feed have evolved. For small and medium aquaculture farms and character fisheries, the extruded fish feed equipment and device production line specializes in the production of various types and specifications of extruded aquatic fish feed.

Contacter maintenant

Dry Floating Fish Feed Pellet Extruder Machine1 Introduction High-protein extruded feed pellets, high-protein content material, fish develop quickly, absorb well, and feed waste is minimal, and fish excrement does less harm to high-quality water, and may be recycled and utilized to increase ecological agriculture.

Contacter maintenant